When checking the tightness of the vacuum brake booster, make sure that its connection to the master brake cylinder is completely tight. In case of leakage, replace the gasket (A).

Checking the tightness of the vacuum brake booster should be carried out on vehicles with serviceable hydraulic wiring.

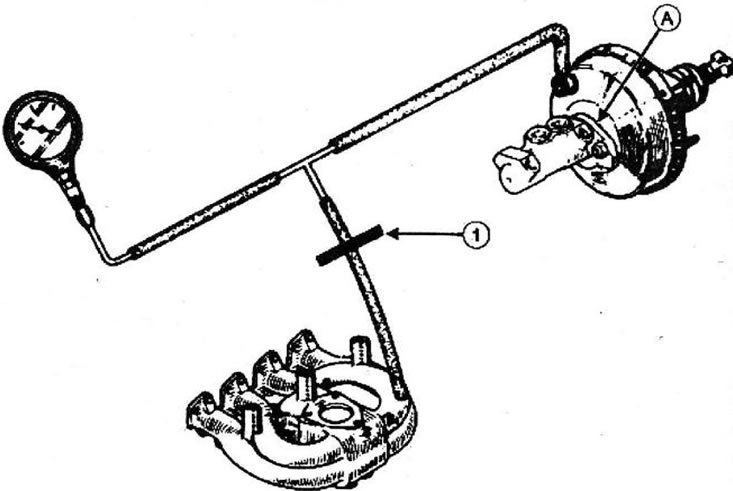

Connect tool between brake booster and vacuum source (intake manifold) by using «tee» and as short a hose as possible.

Start the engine and let it idle for about 10 minutes.

Pinch the hose between «tee» and a source of discharge using a device (Ms. 583) (1).

If the vacuum decreases by more than 33 mbar in 15 seconds, this indicates a leak that may be occurring:

- near the check valve (replace it),

- pusher diaphragm (the vacuum brake booster must be replaced).

With a faulty vacuum booster, the brake system remains operational, but the force applied to the brake pedal for effective braking will be much greater than with a working booster.