Note. Adjust only when bearings are replaced.

Fit input shaft with bearings and pre-adjustment ring B. Vi. 116 0.62mm thick (small outdoor 0).

Install the differential housing, install and torque-tighten the box connector bolts and B-type indicator bracket plate. Vi. 1161 on the mounts of the tripod body.

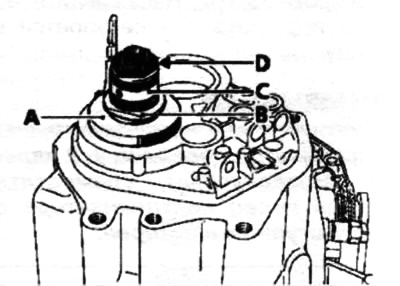

Install:

- bushing B. Vi. 1527 - A;

- support ring B;

- gear ring C;

- nut fully screwed in D.

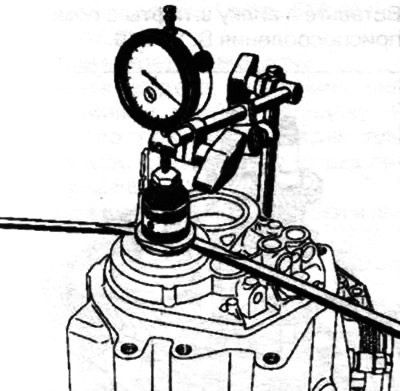

Install a pointer type indicator with a magnetic base.

Rotate the input shaft a few times to get the bearings in place.

Set zero on the indicator scale.

Using two screwdrivers as levers, pull up the input shaft.

Read the pointer type indicator.

Repeat these operations several times in the same sequence.

Determine the average value of the obtained values.

Calculate the thickness for the preload adjustment ring using the following calculation formula:

- ring thickness for pre-adjustment + average value of pointer-type indicator readings - 0.02 (this value must be subtracted to ensure the minimum clearance) = thickness of the ring to be adjusted.

Example (values in mm):

- thickness of ring for pre-adjustment 0.62 + average value of dial indicator 0.50 - 0.02 (this value must be subtracted to ensure the minimum clearance) = thickness of the adjustment ring 1.10.

Note. A set of shims ranging in thickness from 0.86 mm to 1.30 mm in 0.04 mm increments is supplied as a replacement.